- Site Navigation -

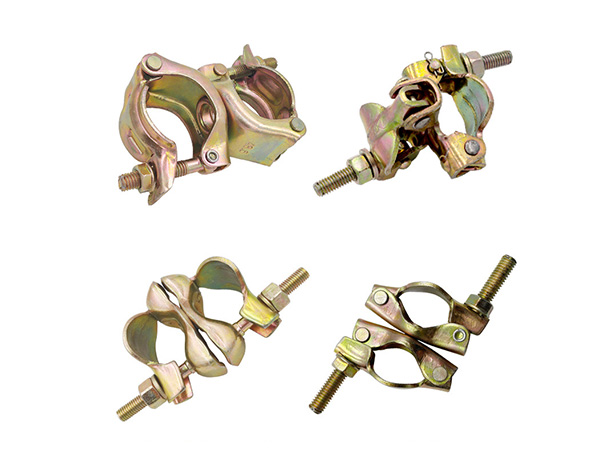

Pressed Steel Coupler

Pressed Steel Coupler to scaffolding connections manufactured through the sheet metal stamping process.......

Pressed Steel Coupler to scaffolding connections manufactured through the sheet metal stamping process. It is a type of fastener widely used in lightweight scaffolding systems by cold pressing in a die and assembled by bolts using high-strength steel plates.

2. Production process characteristics

Stamping forming: using Q235 or Q345 steel plates with a thickness of 2.5-4mm, cold forming by large stamping machines and special molds

Bolt assembly: Multiple stamped parts are combined into complete fasteners by high-strength bolts

Surface treatment: usually hot-dip galvanized or electro-galvanized anti-rust treatment

No Casting Process: The production process is more environmentally friendly compared to traditional cast fasteners

3. Main types

Right-angle stamping fasteners

Used to connect vertically intersecting steel pipes

It consists of two symmetrical stampings combined by bolts

Rotating stamping fasteners

Suitable for any angle connection

Usually with a rotatable holding down mechanism

Butt stamping fasteners

It is used for steel pipe butt extension

It adopts a sleeve stamping structure

4. Performance characteristics

Merit:

Light weight: 30%-40% lighter than traditional cast fasteners

Low cost: high production efficiency and high material utilization

High strength: The cold work hardening effect improves the strength of the material

Neat appearance: high dimensional accuracy and beautiful appearance