- Site Navigation -

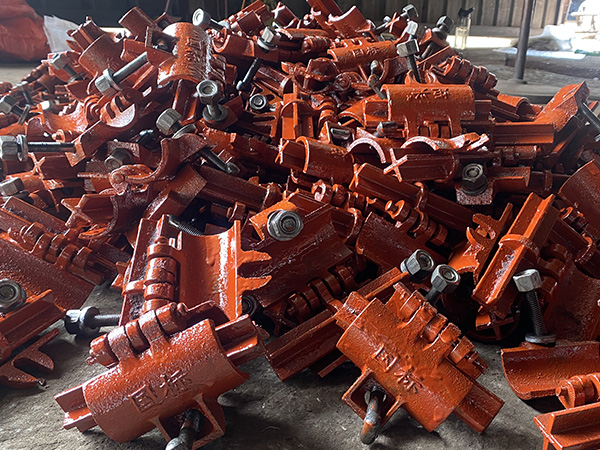

Steel Pipe Clamp

A Steel Pipe Clamp is a fundamental and versatile hardware component designed to securely hold,support,and route pipes in a wide range of industrial,commercial,and residential appli......

Steel Pipe Clamp:An Overview

A Steel Pipe Clamp is a fundamental and versatile hardware component designed to securely hold,support,and route pipes in a wide range of industrial,commercial,and residential applications.Primarily functioning as a support device,it consists of a sturdy steel band or bracket that encircles the pipe and is fastened to a stationary structure,such as a wall,ceiling,or beam.

The primary purpose of a steel pipe clamp is to:

Provide Secure Support:Prevent pipes from sagging under their own weight and the weight of their contents(e.g.,water,gas,chemicals).

Absorb Stress and Vibration:Mitigate the effects of thermal expansion/contraction,water hammer,and machinery vibrations,reducing strain on the pipe system.

Ensure Proper Alignment:Maintain the correct positioning and gradient of pipes for efficient system operation.

Enhance Safety:Prevent accidents caused by loose or falling pipes and protect the pipes from impact damage.

Key Features&Characteristics

Material:Typically made from carbon steel or stainless steel.

Carbon Steel:Common for general-purpose use,often finished with a zinc plating(galvanization)or powder coating for corrosion resistance.

Stainless Steel(e.g.,304 or 316 grade):Preferred for highly corrosive environments,such as chemical plants,marine applications,food processing,and outdoor installations due to its excellent rust resistance.

Design Types:

Two-Bolt Pipe Clamp:The most common type,featuring a two-piece design connected by two bolts.This allows for easy installation and removal without needing to disassemble the entire pipe run.

U-Bolt Clamp:A U-shaped bolt that wraps around the pipe and is secured with two nuts.Often used for heavier pipes and high-vibration applications but requires the pipe to be threaded through.

Single-Bolt Pipe Clamp:A simpler,one-bolt design for lighter-duty applications.

Cushioned/Insulated Clamp:Includes an inner liner made of rubber,PVC,or EPDM.This liner dampens noise and vibration and prevents galvanic corrosion between dissimilar metals(e.g.,a steel clamp on a copper pipe).

Load Capacity:Rated to support specific weights and pipe sizes,ensuring structural integrity and safety.

Common Applications

Steel pipe clamps are indispensable in numerous sectors:

Plumbing:Supporting water supply and drainage lines.

HVAC(Heating,Ventilation,and Air Conditioning):Mounting refrigerant lines,chilled water pipes,and ductwork.

Industrial Processing:Securing complex networks of pipes carrying fluids,gases,and slurries in factories and plants.

Fire Protection Systems:Supporting sprinkler system pipelines.

Electrical Conduit Support:Holding metal conduits that protect electrical wiring.

Marine and Offshore:Securing piping systems on ships and oil platforms(using high-grade stainless steel).

Advantages

High Strength and Durability:Steel provides exceptional load-bearing capacity and longevity.

Corrosion Resistance:Especially when galvanized or made from stainless steel.

Fire Resistance:Unlike plastic alternatives,steel clamps maintain integrity in high-temperature and fire scenarios.

Versatility:Available in a vast range of sizes and styles to fit virtually any pipe diameter and application need.

In summary,the steel pipe clamp is a critical,robust,and reliable component essential for the safe,organized,and efficient installation of piping systems across countless industries.