- Site Navigation -

NEWS LIST

Understanding Scaffold Fittings in Modern Construction

Author:yicheng Date:2026-02-09 10:16:19 Hits:80

Why Scaffold Fittings Matter in Construction

In today’s construction industry, safety, flexibility, and efficiency are more important than ever. One of the key components behind stable temporary structures is Scaffold Fittings. These small but essential connectors link scaffold tubes together, allowing workers to build safe platforms, access systems, and structural frameworks at different heights.

With professional manufacturer-controlled production and standardized factory manufacturing processes, modern Scaffold Fittings are produced with consistent dimensions, reliable materials, and stable performance, enabling batch supply for large-scale construction projects.

From residential buildings to industrial plants and infrastructure projects, Scaffold Fittings form the backbone of safe and adaptable scaffolding systems.

What Are Scaffold Fittings?

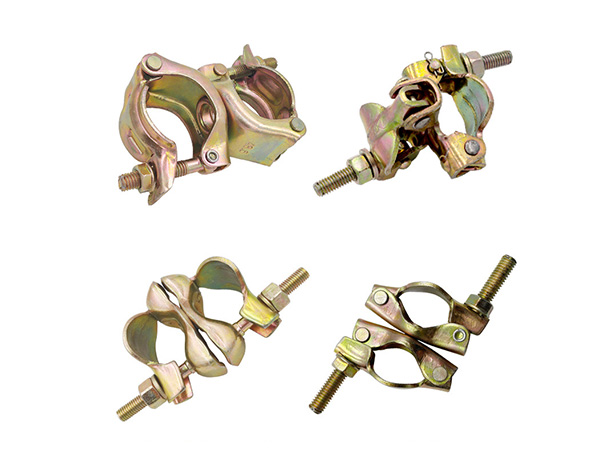

Scaffold Fittings are mechanical connectors used to join steel scaffold tubes at different angles and positions. They allow scaffolding structures to be assembled, adjusted, and dismantled efficiently on site.

Common fittings include right-angle couplers, swivel couplers, sleeve couplers, putlog couplers, beam clamps, and base connectors. Each type serves a specific structural purpose within the scaffold system.

Through factory production, these fittings are manufactured using precision casting, forging, or pressing, followed by machining and surface treatment. This ensures consistent quality and predictable behavior under load.

Structural Role of Scaffold Fittings

The primary function of Scaffold Fittings is to transfer loads safely between scaffold tubes.

They help:

·Maintain frame stability

·Distribute vertical and horizontal loads

·Resist wind and impact forces

·Control movement and vibration

·Prevent displacement and collapse

Without properly designed fittings, even high-quality scaffold tubes cannot perform safely. Manufacturer production standards ensure that each fitting can handle the designed clamping force and load transfer requirements in real working conditions.

Load Performance and Safety Design

Load performance is a critical factor in Scaffold Fittings.

When workers, materials, and equipment are placed on a scaffold, the load travels through the platform, into the tubes, and finally through the fittings into the supporting structure. Scaffold Fittings must resist tension, shear, and compression simultaneously.

Factory-produced fittings undergo testing to verify slip resistance, clamping strength, and deformation limits. This controlled production approach ensures that batch-supplied Scaffold Fittings provide consistent safety performance across large projects.

Material Selection and Durability

Material quality directly influences the lifespan and reliability of Scaffold Fittings.

Most fittings are produced from carbon steel, alloy steel, or malleable iron, offering good strength and toughness. Surface treatments such as galvanizing or coating improve corrosion resistance, especially for outdoor and coastal construction environments.

During factory production, material sourcing and finishing processes are strictly controlled to maintain uniform strength and corrosion protection for long-term use.

Installation Flexibility and Efficiency

One major advantage of Scaffold Fittings is their flexibility.

Unlike rigid modular systems, fittings allow tubes to be connected at almost any angle and position. This makes scaffolding adaptable to irregular building shapes, complex facades, and industrial equipment layouts.

Factory production ensures accurate thread dimensions and smooth surfaces, making on-site installation faster and reducing the risk of misalignment. Manufacturer batch supply also supports rapid deployment for large construction schedules.

Quality Control Through Factory Production

Professional Scaffold Fittings Manufacturers rely on factory-based systems to guarantee product consistency and safety.

Typical production and inspection steps include:

·Forging or casting

·CNC machining

·Heat treatment

·Surface coating

·Dimensional inspection

·Load and slip testing

These processes ensure that every Scaffold Fitting meets engineering requirements before delivery. Factory batch production also enables stable supply for long-term construction projects and infrastructure developments.

Applications of Scaffold Fittings in Modern Projects

Scaffold Fittings are widely used in:

·Building facade construction

·Bridge maintenance

·Industrial plant installation

·Shipbuilding and repair

·Power station projects

·Infrastructure development

Thanks to manufacturer production and factory supply capability, Scaffold Fittings can be delivered in large quantities and customized for different load ranges and connection styles.

Sustainability and Reusability

Sustainability is becoming increasingly important in construction. Scaffold Fittings support this goal through reusability and durability.

High-quality fittings can be used repeatedly across multiple projects, reducing material waste. Factory production also minimizes scrap and improves manufacturing efficiency.

By extending service life and reducing replacement frequency, Scaffold Fittings contribute to more environmentally responsible construction practices.

Future Trends in Scaffold Fittings Technology

As construction technology evolves, Scaffold Fittings manufacturing is also improving.

Factories are introducing automated forging, digital inspection, and advanced coating technologies to enhance precision and corrosion resistance. These innovations improve consistency and performance while supporting large-scale batch supply.

With urban development and infrastructure expansion continuing worldwide, demand for reliable Scaffold Fittings will keep growing in modern construction systems.

Conclusion: Choosing Reliable Scaffold Fittings for Construction Safety

Understanding Scaffold Fittings is essential for building safe, efficient, and flexible scaffolding systems in modern construction.

By working with a professional Scaffold Fittings Manufacturer supported by factory production and bulk supply capability, contractors and engineers gain consistent quality, reliable performance, and stable delivery for large projects.

Whether for commercial buildings, industrial facilities, or infrastructure works, Scaffold Fittings remain a critical component in ensuring safety and productivity across the construction industry.

References

GB/T 7714:Jia L, Liu H, Chen Z, et al. Mechanical properties of right-angle couplers in steel tube–coupler scaffolds[J]. Journal of Constructional Steel Research, 2016, 125: 43-60.

MLA:Jia, Li, et al. "Mechanical properties of right-angle couplers in steel tube–coupler scaffolds." Journal of Constructional Steel Research 125 (2016): 43-60.

APA:Jia, L., Liu, H., Chen, Z., Liu, Q., & Wen, S. (2016). Mechanical properties of right-angle couplers in steel tube–coupler scaffolds. Journal of Constructional Steel Research, 125, 43-60.