- Site Navigation -

NEWS LIST

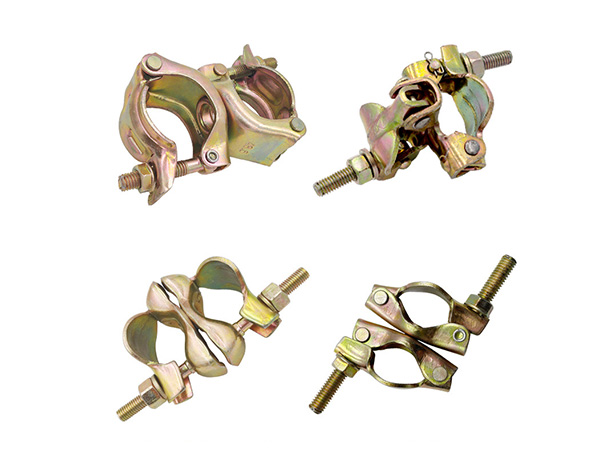

What Are the Load Capacity Ratings for Common Scaffold Couplers?

Author:yicheng Date:2025-09-03 17:50:56 Hits:95

Load Capacity Ratings for Common Scaffold Couplers

Scaffold coupler load capacities are strictly regulated by standards like EN 12811-1(EU),AS/NZS 1577(Australia/New Zealand),and ANSI/ASSE A10.8(U.S.)to ensure structural safety.Ratings vary by coupler type(each designed for specific force directions)and material(hot-dip galvanized steel is the industry standard for strength and corrosion resistance).Below is a detailed breakdown of load capacities for the most common types,plus key caveats to avoid overloading.

1.Key Definitions:Critical Load Types

First,clarify the two main forces couplers must resist—this defines their real-world performance:

Shear Load:Force that tries to"slice"the coupler(e.g.,horizontal pressure from scaffold planks,workers,or equipment).

Tensile Load(Pull-Out Load):Force that tries to pull the coupler apart(e.g.,vertical tension from hanging loads or scaffold movement).

2.Load Capacity Ratings for Common Couplers

Exact ratings may vary slightly by manufacturer,so always check the coupler’s certification label(required by standards)for precise values.Below are typical minimum ratings(per standard requirements):

A.Right-Angle Couplers

Primary Use:Connect vertical standards(poles)to horizontal ledgers—the most common coupler in scaffold frames.

Minimum Shear Load:≥15 kN(equivalent to~1500 kg under Earth’s gravity,for practical reference).

Minimum Tensile Load:≥6 kN(equivalent to~600 kg).

Why This Matters:This coupler bears the core weight of the scaffold(planks,workers,tools),so its high shear capacity is critical for preventing frame collapse.

B.Swivel Couplers

Primary Use:Connect two tubes at any angle(e.g.,diagonal braces for lateral stability,non-right-angle joints on irregular surfaces).

Minimum Shear Load:≥15 kN(~1500 kg)—same as right-angle couplers,as it must resist horizontal forces from bracing.

Minimum Tensile Load:≥6 kN(~600 kg).

Note:While it allows angular adjustment,its load capacity does not decrease when used at non-90°angles(as long as installed correctly).

C.Putlog Couplers

Primary Use:Attach horizontal putlogs(short tubes that support scaffold planks)to vertical standards—designed for lighter,localized loads.

Minimum Shear Load:≥7.5 kN(~750 kg).

Minimum Tensile Load:≥3 kN(~300 kg).

Limitation:Never use for heavy load-bearing joints(e.g.,main ledger connections)—its lower capacity is only suitable for plank support.

D.Sleeve Couplers

Primary Use:Join two vertical standards end-to-end to extend scaffold height(only for straight,in-line connections).

Minimum Axial Compression Load:≥20 kN(~2000 kg)—focused on compression(supporting downward weight of the scaffold above),not tension.

Key Note:Not designed for tensile forces(pulling apart),so never use it for horizontal tube extensions or joints that may experience tension.

3.Factors That Reduce Actual Load Capacity

Even if a coupler meets standard ratings,real-world performance can drop sharply due to these issues:

Damage/Wear:Corrosion,bent jaws,stripped threads,or cracks cut load capacity by 50%or more—never use damaged couplers.

Incorrect Tightening:Under-tightening(bolt torque below 45-55 N·m for steel couplers)breaks the coupler’s grip on tubes;over-tightening strips threads or deforms the body.

Mismatched Tubes:Using a 48.3mm-standard coupler on smaller/larger tubes(e.g.,42mm)creates a loose fit,eliminating load-bearing ability.

Extreme Conditions:Temperatures below-10°C or above 50°C weaken steel;saltwater(coastal areas)accelerates corrosion,reducing capacity over time.

4.Safety Rules for Load Capacity

Never Exceed Ratings:If a right-angle coupler is rated for 15 kN shear,avoid stacking heavy materials(e.g.,concrete bags)directly above the joint.

Calculate Total Loads:Account for dead load(scaffold tubes/planks),live load(workers/tools),and environmental load(wind/snow—add 0.5-1.0 kN/m²for wind in exposed areas).

Use Certified Couplers:Only buy couplers with visible certification(e.g.,CE mark for EN 12811-1)and batch test reports—unbranded couplers often fail load tests.

Inspect Before Use:Check for corrosion,cracks,and proper tube fit every time—a small defect can collapse the entire load capacity.

Always reference the manufacturer’s specs and national standards for exact ratings.Overloading or misusing couplers is the top cause of scaffold failures,so prioritizing capacity compliance is non-negotiable.