- Site Navigation -

NEWS LIST

Application Scenarios of Steel Structure Support

Author:yicheng Date:2025-09-02 11:21:31 Hits:128

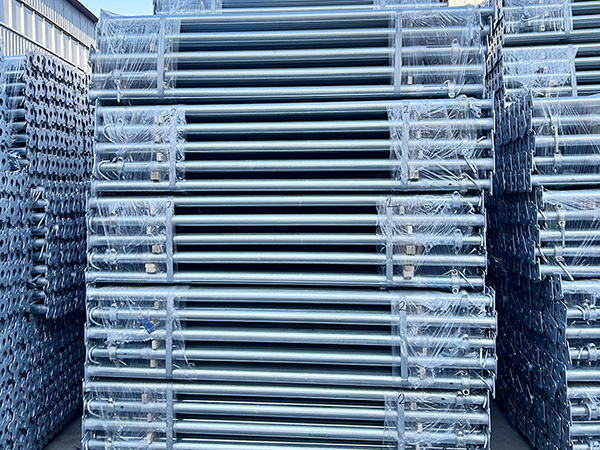

Application Scenarios of Steel Structure Support

Steel structure support plays a pivotal role in diverse construction fields,adapting to varied load demands and environmental conditions to ensure structural safety and construction efficiency.

In building construction,it is indispensable for both residential and commercial projects.For high-rise residential floors,vertical steel supports(e.g.,adjustable steel props withΦ48-Φ60mm tubes)support concrete formwork during pouring,bearing slab and beam loads(15-30kN per unit)to maintain flatness.In commercial complexes,lateral steel braces(angle steels L50×5-L80×8)reinforce steel frame cores(elevator shafts,stairwells)against wind loads,preventing sway.For prefabricated buildings,inclined steel supports stabilize precast walls and panels during installation,holding them in place until permanent fastening.

In bridge engineering,steel supports tackle heavy-load and dynamic scenarios.During bridge beam erection,heavy-duty vertical supports(Φ89mm tubes,load capacity≥35kN)cradle precast T-beams or box girders,ensuring precise alignment.For bridge maintenance,temporary lateral steel braces(channel steels C16-C20)reinforce aging deck structures,resisting traffic-induced vibrations.In cable-stayed bridge construction,inclined steel struts connect tower segments,transferring compressive forces to the foundation.

In tunnel projects,steel supports endure harsh underground conditions.During tunnel excavation,steel arch supports(assembled from I-beams or U-steels)line the tunnel crown,resisting soil and water pressure to prevent collapse.For shotcrete lining construction,horizontal steel supports(seamless tubes)hold formwork,ensuring uniform lining thickness.In metro tunnel stations,vertical steel props support platform slabs during construction,with galvanized surfaces resisting underground humidity.

In industrial facilities,steel supports meet specialized needs.In factories,large-span steel truss roofs rely on vertical supports(Φ76mm tubes)spaced 1.5-2m apart,bearing equipment and snow loads.For heavy machinery(generators,conveyors),adjustable steel supports with anti-vibration pads stabilize bases,reducing operational noise.In petrochemical plants,corrosion-resistant steel braces(stainless steel or galvanized)reinforce pipe racks,withstanding chemical fumes.

Across all scenarios,steel supports’high strength,adjustability,and durability make them irreplaceable,adapting to diverse construction challenges while ensuring safety and quality.