- Site Navigation -

NEWS LIST

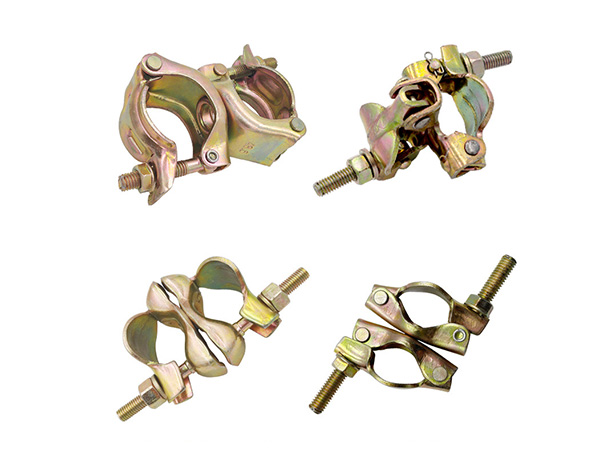

A Beginner’s Guide to Coupler Load Capacity

Author:yicheng Date:2025-12-21 16:09:39 Hits:80

Understanding Coupler Load Capacity

The Coupler plays a critical role in many construction and industrial systems, especially in scaffolding, formwork, and structural connections. For beginners, one of the most important concepts to understand is coupler load capacity, which directly affects safety, performance, and compliance with engineering standards.

Coupler load capacity refers to the maximum force a coupler can safely withstand under specific conditions. Whether used in temporary structures or long-term installations, understanding this capacity is essential to prevent structural failure. Manufacturers with standardized production processes carefully test and control coupler performance to ensure consistent load-bearing capability, particularly when supplying components in large volumes.

This guide explains the basics of coupler load capacity, how it is determined, and why it matters in real-world applications.

What Is Coupler Load Capacity?

Coupler load capacity is the maximum load that a coupler can carry without deformation, slippage, or failure. This load may be expressed as axial load, tensile load, compressive load, or slip resistance, depending on the coupler’s design and application.

A Coupler typically connects two structural elements—such as tubes, pipes, or bars—allowing forces to be transferred safely between them. The load capacity defines the safe working limit and is determined through engineering calculations and physical testing.

Understanding this value helps engineers and site supervisors choose the correct coupler type for each application.

Why Coupler Load Capacity Is Important

Structural Safety

Exceeding the rated load capacity of a Coupler can lead to slippage, deformation, or sudden failure. In scaffolding systems, this may cause instability or collapse, posing serious safety risks.

Compliance with Standards

Many construction projects must comply with regional or international standards. Proper load-rated couplers ensure that structural systems meet safety and regulatory requirements.

Performance Consistency

Couplers with clearly defined load capacities provide predictable performance. This consistency is especially important in projects requiring repeated use or large quantities of components.

Factors That Affect Coupler Load Capacity

Several factors influence how much load a Coupler can safely handle:

Material Strength

Most couplers are made from carbon steel or alloy steel. The material grade directly affects strength, durability, and resistance to fatigue.

Design and Geometry

The shape, thickness, and contact surface of a coupler determine how forces are distributed. Well-designed couplers reduce stress concentration and improve load performance.

Manufacturing Accuracy

Precision in production ensures proper fit and contact between connected components. Controlled production processes help manufacturers maintain uniform load capacity across batches.

Installation Conditions

Improper installation, misalignment, or contamination can significantly reduce actual load performance, even if the coupler itself meets design specifications.

How Coupler Load Capacity Is Tested

Manufacturers determine coupler load capacity through standardized testing procedures. These tests simulate real working conditions and measure how the Coupler behaves under increasing loads.

Common tests include:

·Slip resistance testing

·Tensile and compressive load testing

·Fatigue testing under repeated loading

Testing results define the rated load capacity and safety factors. For projects requiring bulk supply, manufacturers rely on consistent testing protocols to ensure each coupler meets the same performance standards.

Common Applications of Load-Rated Couplers

Couplers with verified load capacity are widely used in:

·Scaffolding systems

·Temporary support structures

·Formwork connections

·Industrial maintenance platforms

·Modular construction systems

In these applications, the Coupler must reliably transfer loads without compromising the overall structural system.

Choosing the Right Coupler for Your Project

For beginners, selecting the right Coupler involves more than just size compatibility. Key considerations include:

·Required load capacity

·Type of load (static or dynamic)

·Environmental conditions

·Installation method

Working with a manufacturer that supports stable production and bulk supply helps ensure consistent quality, especially for large or long-term projects.

Common Misunderstandings About Coupler Load Capacity

One common mistake is assuming all couplers of similar size have the same load capacity. In reality, design details, material grade, and manufacturing quality can lead to significant differences.

Another misunderstanding is ignoring safety factors. The rated load capacity already accounts for safety margins, but exceeding it can quickly reduce reliability.

Future Trends in Coupler Design and Production

As construction methods evolve, coupler designs continue to improve. Advanced materials, automated manufacturing, and stricter testing standards are enhancing load performance and consistency.

Manufacturers are also optimizing production systems to support large-scale projects, ensuring reliable supply without compromising quality.

Conclusion: Why Coupler Load Capacity Matters

Understanding Coupler load capacity is essential for anyone involved in construction or industrial assembly. From safety and compliance to performance and durability, load capacity defines how a Coupler performs under real working conditions.

By choosing couplers with verified load ratings and sourcing them from a manufacturer with controlled production and bulk supply capability, beginners and professionals alike can ensure safer, more reliable structural systems. As demand for efficient construction continues to grow, the Coupler will remain a small but critical component with a big impact on structural safety.

References

GB/T 7714:Link R E. An introduction to the design and behavior of bolted joints[J]. Journal of Testing and Evaluation, 1991, 19(5): 417-418.

MLA:Link, R. E. "An introduction to the design and behavior of bolted joints." Journal of Testing and Evaluation 19.5 (1991): 417-418.

APA:Link, R. E. (1991). An introduction to the design and behavior of bolted joints. Journal of Testing and Evaluation, 19(5), 417-418.