- Site Navigation -

NEWS LIST

How Couplers Can Improve Construction Efficiency

Author:yicheng Date:2025-10-20 09:40:43 Hits:71

In the ever-evolving world of construction, efficiency and reliability are essential for completing projects on time and within budget. Engineers and contractors are constantly searching for smarter tools and connection methods that make structures stronger while saving time and labor.

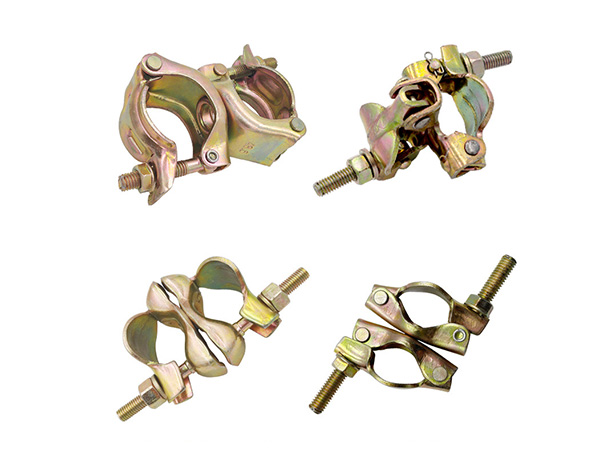

One such innovation is the Coupler — a compact yet powerful component that’s reshaping how reinforcement bars are joined. From skyscrapers to bridges, couplers help improve safety, sustainability, and structural integrity.

Many builders now choose China Coupler manufacturers with factory-direct bulk supply, ensuring consistency, affordability, and international quality standards across large-scale projects.

Understanding What a Coupler Is

A Coupler (or rebar coupler) is a mechanical connector used to join two reinforcing steel bars end-to-end, creating a continuous load path. Unlike traditional lap splicing, which requires long bar overlaps and extra material, couplers deliver a direct and efficient connection.

Why Couplers Matter:

·Higher load transfer efficiency without overlap

·Faster installation, reducing on-site labor hours

·Less steel usage, cutting overall costs and material waste

·Greater flexibility for prefabrication and modular construction

When sourced from a China factory manufacturer, couplers are precisely machined using advanced threading equipment and high-grade carbon steel, offering unmatched consistency and performance under heavy structural loads.

1. Reducing On-Site Labor and Installation Time

Traditional rebar connections require bending, welding, or overlapping—processes that demand both time and skilled labor. With couplers, the process becomes quick, clean, and reliable.

Practical Benefits:

·Workers can assemble connections in minutes, not hours.

·No welding or flame-cutting is required, eliminating fire hazards.

·Labor requirements drop significantly — especially on large construction sites.

In large-scale civil projects such as tunnels, high-rises, and infrastructure works, contractors using bulk couplers from China suppliers often report installation time reductions of 30–50%. The result: faster progress, fewer delays, and greater overall site efficiency.

2. Enhancing Structural Safety and Performance

Efficiency isn’t just about speed — it’s about ensuring structural reliability. Couplers maintain the full strength of the reinforcement bar, transmitting tension and compression without weakening the joint.

This makes them ideal for projects in seismic zones, high-load areas, and critical structural components like columns and foundations. Unlike welded joints, which can develop heat-induced stress points, couplers provide a cold mechanical bond that retains full bar capacity.

Manufacturers in China have refined the process with precision threading and automated inspection systems, ensuring every coupler meets international standards such as ISO 15835 or BS 8110.

For safety-focused builders, investing in China factory-manufactured couplers means fewer failures, easier inspection, and peace of mind on every project.

3. Supporting Prefabrication and Modular Construction

The shift toward modular construction has changed how projects are planned and executed. Couplers make modular assembly practical by enabling pre-cast or pre-assembled sections to be easily joined on-site.

Key Advantages:

·Simplifies transportation and on-site assembly

·Minimizes misalignment between precast elements

·Improves precision in vertical and horizontal joints

By using threaded couplers from China bulk suppliers, contractors can ensure consistent compatibility across multiple batches and project phases. The result is a smoother assembly process and a cleaner, more controlled construction environment.

4. Lowering Material Waste and Environmental Impact

Sustainability and cost savings often go hand-in-hand — and couplers support both. By removing the need for lengthy overlaps, couplers reduce the total steel used per connection by up to 25%.

Sustainability Benefits:

·Less scrap steel waste on-site

·Lower CO₂ emissions due to reduced material use

·No energy-intensive welding required

·Longer service life with corrosion-resistant coatings

Many China Coupler factories use recycled steel and automated forging lines to produce eco-friendly, high-strength products suitable for global export. When you purchase directly from these China suppliers in bulk, you not only cut costs but also support sustainable manufacturing.

5. Cost Efficiency through Bulk Supply and Standardization

Another major advantage of choosing a China Coupler manufacturer is the cost-to-quality ratio. Large-scale production, automated threading, and material efficiency allow factories to offer competitive pricing without compromising quality.

Why Bulk Coupler Supply Makes Sense:

·Standardized dimensions reduce assembly errors

·Factory testing guarantees performance uniformity

·Economies of scale lower unit costs

·Fast global delivery through streamlined logistics networks

By sourcing directly from a China factory, contractors gain access to technical customization options (thread size, length, tensile strength) while maintaining budget control — a perfect balance between affordability and dependability.

6. Increasing Project Efficiency with Better Logistics

On a construction site, coordination between teams, materials, and schedules is key. Couplers simplify logistics by reducing the need for long rebars and on-site fabrication. Pre-threaded bars can be delivered ready-to-use, cutting storage space and handling costs.

Moreover, bulk coupler supply from China-based manufacturers ensures consistency across shipments — avoiding mismatched threads or incompatible connectors, which can delay assembly.

This efficiency in logistics translates directly into reduced downtime, faster turnover, and smoother construction workflows.

Conclusion

From saving time and materials to improving safety and sustainability, Couplers are a small investment that delivers enormous returns in construction efficiency.

For global builders and contractors, sourcing Couplers from a China factory manufacturer offering bulk supply ensures precision engineering, uniform quality, and reliable delivery.

In an industry where every connection matters, a well-made Coupler is more than just a joint — it’s a key to stronger, faster, and greener construction.

High-quality Couplers from China suppliers continue to prove that even the smallest components can make the biggest difference in the success of a project.

References

GB/T 7714:Liu T, Lu J, Liu H. Experimental and numerical studies on the mechanical performance of a wall-beam-strut joint with mechanical couplers for prefabricated underground construction[J]. International Journal of Concrete Structures and Materials, 2020, 14(1): 36.

MLA:Liu, Tingjin, Jiandong Lu, and Hongyuan Liu. "Experimental and numerical studies on the mechanical performance of a wall-beam-strut joint with mechanical couplers for prefabricated underground construction." International Journal of Concrete Structures and Materials 14.1 (2020): 36.

APA:Liu, T., Lu, J., & Liu, H. (2020). Experimental and numerical studies on the mechanical performance of a wall-beam-strut joint with mechanical couplers for prefabricated underground construction. International Journal of Concrete Structures and Materials, 14(1), 36.