- Site Navigation -

NEWS LIST

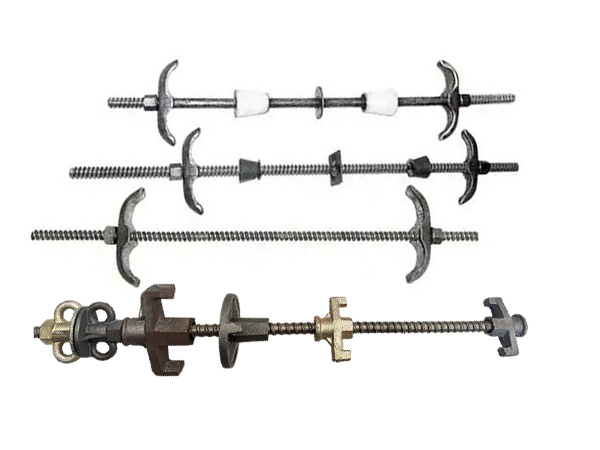

How Wall-Tie Bolt Design Impacts Structural Stability

Author:yicheng Date:2026-01-03 10:34:52 Hits:117

In modern concrete and formwork construction, the Wall-Tie Bolt plays a critical yet often underestimated role in maintaining structural stability. Acting as a temporary but essential load-transferring element, wall-tie bolts ensure formwork alignment, resist lateral pressure, and help achieve accurate concrete placement.

Although wall-tie bolts are typically removed or cut after concrete curing, their performance during construction directly affects dimensional accuracy and structural integrity. For engineers, contractors, and buyers sourcing from manufacturers with stable production and bulk supply capability, understanding how wall-tie bolt design impacts structural stability is essential for safe and efficient construction operations.

1. The Structural Role of Wall-Tie Bolt Systems

A wall-tie bolt is designed to hold opposing formwork panels together while resisting the lateral pressure exerted by freshly poured concrete. During concrete placement, pressure increases rapidly and unevenly, making reliable tensile resistance critical.

Proper wall-tie bolt design ensures:

Controlled spacing between formwork panels

Uniform pressure distribution

Prevention of formwork bulging or displacement

Without adequate design consideration, even minor deformation can compromise wall thickness accuracy and surface quality.

2. Load Behavior and Tensile Performance

Wall-tie bolts primarily operate under tensile loads. Their ability to resist elongation under pressure determines how well formwork systems maintain alignment during concrete pouring.

Design factors such as bolt diameter, thread profile, and effective length directly affect tensile performance. Well-designed wall-tie bolts minimize elastic deformation, allowing the formwork system to behave as a unified structure rather than independent panels.

From a manufacturing perspective, maintaining consistent tensile properties across production batches is critical, especially when wall-tie bolts are supplied in large volumes for major construction projects.

3. Material Selection and Mechanical Properties

Material choice is one of the most influential aspects of wall-tie bolt design. Steel is commonly used due to its high tensile strength and predictable mechanical behavior.

However, variations in material composition can significantly affect performance. Controlled material sourcing and standardized production processes help ensure that each wall-tie bolt meets the required strength and ductility standards.

Manufacturers with established production systems focus on consistency rather than maximum strength alone, recognizing that balanced mechanical properties contribute more effectively to overall structural stability.

4. Thread Design and Load Transfer Efficiency

Thread geometry plays a key role in how loads are transferred between the wall-tie bolt and associated components such as nuts and anchor plates.

Poor thread design can lead to uneven stress distribution, localized wear, or premature failure. Precision machining during production ensures uniform thread engagement and reduces the risk of slippage under load.

For bulk supply scenarios, consistent thread quality is essential to ensure compatibility and predictable performance across all supplied components.

5. Dimensional Accuracy and Formwork Alignment

Accurate wall thickness depends heavily on dimensional control of wall-tie bolts. Variations in length or diameter can result in uneven spacing between formwork panels.

Precision-controlled production processes help manufacturers maintain tight tolerances, ensuring that each wall-tie bolt contributes to accurate formwork geometry. This accuracy not only improves structural alignment but also reduces the need for corrective work after concrete curing.

6. Durability During Repeated Use

In many construction environments, wall-tie bolts are reused multiple times before replacement. Their durability under repeated loading cycles directly affects site efficiency and safety.

Surface condition, material fatigue resistance, and thread wear all influence service life. Reliable manufacturers incorporate quality control measures throughout production to ensure that wall-tie bolts maintain performance even after multiple uses.

7. Production Consistency and Bulk Supply Reliability

For large-scale projects, consistency matters as much as individual component strength. Variations in wall-tie bolt performance across batches can lead to uneven formwork behavior and increased risk during concrete placement.

Manufacturers with stable production capacity and bulk supply experience are better positioned to deliver uniform products that behave predictably on site. Consistent production standards reduce installation issues and simplify quality assurance for contractors.

8. Installation Efficiency and On-Site Safety

Well-designed wall-tie bolts contribute to faster installation and safer working conditions. Smooth thread engagement, accurate dimensions, and reliable tensile behavior allow crews to assemble formwork systems efficiently.

Reducing installation complexity not only saves time but also minimizes the likelihood of improper tightening or misalignment, both of which can affect structural stability during concrete pouring.

Conclusion

The Wall-Tie Bolt is a fundamental component in formwork systems, directly influencing structural stability during critical construction stages. Its design affects load resistance, alignment accuracy, and overall formwork performance under concrete pressure.

Beyond basic dimensions, effective wall-tie bolt performance depends on thoughtful design, controlled manufacturing processes, and consistent production quality. When sourced from manufacturers capable of stable production and reliable bulk supply, wall-tie bolts contribute to safer construction practices and more predictable structural outcomes.

Understanding how wall-tie bolt design impacts structural stability allows engineers and buyers to make informed decisions, ensuring that temporary construction systems perform reliably when it matters most.

References

GB/T 7714:Standard A A C I. Guide to Formwork for Concrete[J]. 2004.

MLA:Standard, An ACI. "Guide to Formwork for Concrete." (2004).

APA:Standard, A. A. (2004). Guide to Formwork for Concrete.