- Site Navigation -

NEWS LIST

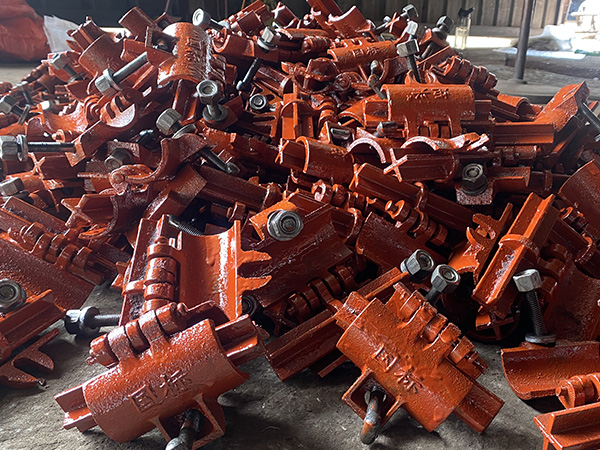

How Often Should Scaffold Couplers Be Inspected for Damage or Wear?

Author:yicheng Date:2025-09-03 17:48:37 Hits:128

Scaffold couplers are critical load-bearing components of scaffolding systems,and regular inspection is essential to prevent structural failures and ensure worker safety.The frequency of inspections is governed by national safety standards(e.g.,BS EN 12811-1 in Europe,OSHA standards in the U.S.)and industry best practices,with intervals varying based on usage,environment,and regulatory requirements.Below is a detailed breakdown of inspection frequencies and key considerations:

1.Pre-Use Inspection(Every Time Before Use)

This is the most frequent and non-negotiable inspection,as it catches immediate issues that could pose risks during a work shift.

Who performs it:The scaffolding user(e.g.,worker,scaffolder)or the designated"competent person"(someone trained and authorized to assess scaffolding safety).

When:Before the coupler is installed in a scaffold,or before the scaffold is used each day/shift.

What to check:

Visible damage(cracks,bent or distorted jaws,broken threads on bolts/nuts).

Wear(e.g.,excessive gap between coupler jaws,worn bolt heads that can’t be tightened with standard tools).

Missing parts(e.g.,missing nuts,split pins for swivel couplers).

Contamination(dirt,oil,or debris that could prevent proper tightening or seating on tubes).

2.Regular Periodic Inspections(At Least Every 7 Days)

For in-use scaffolding(scaffolds that are assembled and actively used),periodic inspections are mandated to account for wear from repeated use,environmental stress,or accidental impacts.

Who performs it:A competent person(not just the end user—this requires formal training in scaffolding safety and inspection).

When:

Minimum interval:Every 7 days from the date of the last inspection(required by standards like BS EN 12811-1 and UK HSE guidelines).

Shorter intervals if:

The scaffold is in a high-traffic area(e.g.,near construction machinery that could hit it).

The couplers are exposed to harsh conditions(e.g.,heavy rain,saltwater,or corrosive chemicals).

The scaffold is used for heavy loads(e.g.,construction materials,equipment).

What to check:

Loosened couplers(due to vibration or thermal expansion/contraction).

Signs of corrosion(especially in outdoor or humid environments).

Wear on contact points(where the coupler grips the scaffold tube—excessive wear reduces clamping force).

Damage from impacts(e.g.,dented jaws from falling tools or materials).

3.Post-Incident or Event-Driven Inspections(Immediately After)

Inspections are required immediately if the scaffolding(and its couplers)may have been compromised by an unexpected event.Common triggers include:

Severe weather(high winds,heavy rain,snow,or lightning—can loosen couplers or cause corrosion acceleration).

Accidental impacts(e.g.,a vehicle,crane load,or falling object hitting the scaffold).

Modifications or repairs(e.g.,after adding/removing scaffold tubes,which involves repositioning or reusing couplers).

A near-miss or safety concern(e.g.,a worker noticing a loose coupler or unusual movement in the scaffold).

Who performs it:A competent person,who may need to take the scaffold out of use until repairs(e.g.,replacing damaged couplers)are completed.

4.Long-Term Storage or Reuse Inspections(Before Reinstallation)

Couplers that are removed from a scaffold,stored,or reused in a new system require a thorough inspection to ensure they haven’t degraded during storage.

When:

Before removing from storage(even if stored for a short period—dust,moisture,or pest damage can occur).

Before reinstalling in a new scaffold(even if the coupler was"undamaged"when removed).

What to check:

Corrosion(common in damp storage areas—check for rust on bolts,jaws,or hinge points).

Thread damage(storage can cause debris to jam threads,making bolts impossible to tighten).

Deformation(e.g.,couplers stacked incorrectly may bend or warp).

Functional testing(e.g.,ensuring bolts can be tightened to the required torque without stripping threads).

Key Regulatory Reference

In Europe(including the UK),BS EN 12811-1:2003+A1:2011(Scaffolding—Performance requirements and general design)mandates periodic inspections of couplers as part of overall scaffold safety.

The UK’s Health and Safety Executive(HSE)further specifies that in-use scaffolding must be inspected every 7 days,with records kept for at least 12 months.

Critical Note:Documentation

All inspections(pre-use,periodic,post-incident)must be recorded in writing(or digitally)with details including:

Date and time of inspection.

Name of the competent person.

Scaffold location and coupler identifiers(if labeled).

Findings(e.g.,"2 couplers with worn jaws replaced").

Action taken(e.g.,"Scaffold cleared for use"or"Scaffold isolated until repairs").

This documentation is not only a regulatory requirement but also critical for tracking coupler lifespan and identifying recurring issues(e.g.,frequent corrosion in a specific area).