- Site Navigation -

NEWS LIST

Step-by-Step Guide: How to Install Steel Support Systems Correctly

Author:yicheng Date:2025-11-11 22:38:05 Hits:152

The Foundation of Every Safe Structure

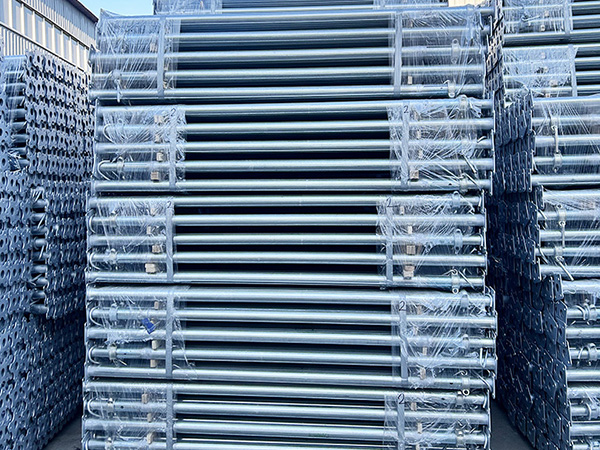

When it comes to construction integrity, Steel Support components are indispensable. They serve as the load-bearing framework for beams, columns, and platforms—ensuring stability and strength throughout a building’s lifecycle.

For engineers, site supervisors, and procurement specialists working with a China supplier or Chinese manufacturer, understanding the correct installation process is vital. A properly installed Steel Support system not only guarantees safety but also enhances durability and long-term performance under dynamic conditions.

What Is a Steel Support System?

A Steel Support system includes the network of steel beams, brackets, and connectors designed to hold up structural loads. It distributes forces evenly and prevents deformation in both vertical and horizontal directions.

Because these supports are critical for stability, they must be designed and fabricated to withstand extreme pressure, vibration, and temperature changes. That’s why sourcing high-quality materials from a certified Chinese manufacturer with bulk supply capabilities is crucial for modern infrastructure and industrial projects.

Selecting the Right Material and Standard

High-rise buildings, bridges, and heavy industrial plants rely on steel components that comply with international standards. Before installation, ensure that your Steel Supports conform to:

·ASTM A36 / A572 / A992 – Defines strength and ductility of structural steels.

·EN 10025-2 – Specifies mechanical performance and composition of non-alloy steel structures.

·ISO 9001 Certification – Ensures manufacturing quality and consistency in production lines.

Choosing compliant materials ensures uniform load resistance, precise fitment, and long-term corrosion protection—especially for outdoor or marine environments.

Step 1: Site Assessment and Preparation

Before installation, conduct a thorough inspection of the foundation. The base must be level, stable, and debris-free. Verify alignment points and anchoring locations according to the construction blueprint.

Safety preparation is equally essential—workers should wear protective gear, and all lifting machinery should be inspected to prevent accidents during the erection phase.

Step 2: Alignment and Positioning

Precise alignment ensures the overall geometry of the structure remains accurate. Use laser-level tools or digital theodolites to position each Steel Support exactly according to design drawings.

Incorrect alignment can cause uneven load distribution, leading to excessive stress on joints and potential long-term deformation.

Step 3: Anchoring and Connection

Depending on the project design, Steel Supports may be:

·Bolted — Ideal for detachable or adjustable structures.

·Welded — Preferred for permanent joints requiring high rigidity.

Ensure that bolts and nuts meet the same grade as the steel components to prevent galvanic corrosion. For welding, certified welders and post-weld inspections are mandatory to detect cracks or surface defects.

Step 4: Load Distribution and Stability Verification

After connection, verify that all loads are evenly distributed. Engineers should review stress analysis or simulation results to confirm that each Steel Support can carry its designated weight. Reinforce high-stress joints with additional plates or gusset reinforcements if needed.

Step 5: Surface Treatment and Corrosion Protection

To extend service life, apply corrosion-resistant coatings such as:

·Hot-dip galvanization – For outdoor or marine conditions.

·Epoxy paint systems – For industrial or chemical environments.

Some China suppliers offer pre-coated Steel Supports, saving installation time and reducing on-site labor. Always check coating thickness and adhesion quality before final acceptance.

Step 6: Inspection and Documentation

Once installation is complete, perform a full quality inspection:

·Visual checks for weld quality, alignment, and surface defects.

·Torque testing for bolts and anchors.

·Dimensional verification to ensure compliance with drawings.

All records—test certificates, inspection reports, and photos—should be compiled into a quality dossier for future audits or maintenance.

Common Pitfalls to Avoid

·Misalignment due to uneven foundation leveling.

·Over-tightening bolts beyond torque limits.

·Mixing dissimilar metals (causing galvanic corrosion).

·Neglecting post-installation inspection or documentation.

Avoiding these mistakes significantly reduces structural risk and maintenance costs later in the building’s lifecycle.

The Growing Global Market for Steel Supports

With global infrastructure and industrial expansion, demand for Steel Support systems continues to rise. Advanced Chinese manufacturers are meeting this demand with automation, precision fabrication, and standardized bulk supply tailored for export.

These suppliers not only produce according to ASTM and EN standards but also provide customization for complex designs—ensuring both affordability and reliability for international contractors.

Conclusion — Strength Built on Precision

A well-installed Steel Support system defines the longevity and safety of any construction project. Partnering with an experienced China supplier or Chinese manufacturer offering bulk supply and certified materials guarantees consistent quality, technical compliance, and peace of mind.

From site preparation to inspection, every detail matters. When done right, installing Steel Support the correct way ensures your structure stands strong for generations.

References

GB/T 7714:Alashoub Turki Sulaiman M, Liang C. Analysis of Key Points of Steel Structure Construction Technology in Film Engineering Projects[M]//Advances in Frontier Research on Engineering Structures. Singapore: Springer Nature Singapore, 2023: 185-195.

MLA:Alashoub Turki Sulaiman, M., and Chunyu Liang. "Analysis of Key Points of Steel Structure Construction Technology in Film Engineering Projects." Advances in Frontier Research on Engineering Structures. Singapore: Springer Nature Singapore, 2023. 185-195.

APA:Alashoub Turki Sulaiman, M., & Liang, C. (2023). Analysis of Key Points of Steel Structure Construction Technology in Film Engineering Projects. In Advances in Frontier Research on Engineering Structures (pp. 185-195). Singapore: Springer Nature Singapore.